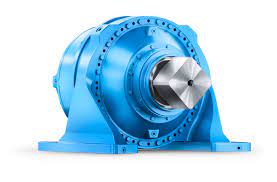

Speed reducers, also known as gearboxes or gear reducers, are mechanical devices designed to decrease the rotational speed of a motor and increase torque (turning force). These are widely used in various industrial and machinery applications.

Here are some key points about speed bumps:

- Basic Operation: Speed reducers contain a set of gears that interact to reduce the output speed compared to the input speed. The reduction ratio is determined by the number of teeth in the gears.

- Gears: Gears can be of various types such as spur, helical or bevel gears depending on the specific application and design requirements.

- Common Applications: Used in a variety of industries and applications, such as heavy machinery, conveyors, conveyor belt systems, industrial mixers, machine tools, and more. They are also used in cars and other vehicles.

- Advantages: Speed reducers offer several advantages, such as the ability to adapt speed and torque to the specific needs of an application. Additionally, they help protect motors by reducing load and enabling more efficient performance.

- Maintenance: They require periodic maintenance to ensure optimal operation. This may include proper lubrication of the gears and inspecting them for wear.

- Special types: In addition to standard speed reducers, there are specialized types for specific applications, such as planetary reducers that offer compact design and higher efficiency.

In summary, speed reducers are essential components in many industrial applications, providing efficient matching of speed and torque to optimize machinery performance.