How are steam turbines used in industrial processes?

Steam turbines are devices that convert the thermal energy of steam into mechanical energy, which can then be used to do work, such as generating electricity or driving machinery in industrial processes. Here is a basic explanation of how steam turbines are used in industrial processes:

Steam generation: First, water vapor must be generated. This is usually achieved by heating water by burning fossil fuels such as coal, natural gas or oil, or by renewable energy processes such as biomass or concentrated solar energy.

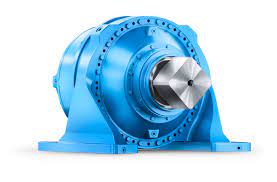

Feeding to the turbine: The steam generated is fed to the steam turbine. The turbine consists of a series of blades mounted on a rotor. When steam flows through these vanes, it exerts a force on them, causing the rotor to rotate.

Mechanical energy generation: The rotation of the turbine rotor is converted into mechanical energy. This mechanical energy can be used directly to drive machines or industrial equipment, or it can be used to generate electricity by coupling it to an electrical generator connected to the rotor.

Electricity production: If the steam turbine is coupled to an electrical generator, the mechanical energy is converted into electricity. This process is commonly used in power plants to generate electrical energy on a large scale.

Rankine Cycle: Most steam turbines operate on a thermodynamic cycle known as the Rankine cycle, which includes steam generation, expansion in the turbine, condensation, and returning water to the starting point to begin the cycle again. .

Industrial Applications: Steam turbines are used in a wide range of industrial applications, such as electricity generation in power plants, energy production for industrial processes, and propulsion in ships and locomotives.

In summary, steam turbines are essential in power generation as they convert the thermal energy of steam into mechanical energy that can be used to perform various tasks in industrial processes or generate electricity.