Optimizing Industrial Operation with Lubrication Pumps

At the heart of industrial machinery, having well-oiled parts is key for everything to work as it should. And this is where lubrication pumps come into play. They are like the little engine that is responsible for distributing oil everywhere, from huge factories to the smallest facilities. Without them, the equipment would wear out faster and not perform as well. In short, they are like the secret to keeping everything running smoothly in the world of industry.

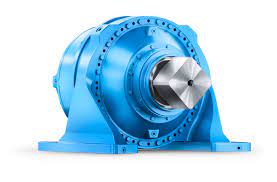

What are Lubrication Pumps and How Do They Work?

Lubrication pumps are devices designed to supply lubricants to different parts of industrial machinery in a controlled and precise manner. They work through a pump mechanism that drives lubricant through pipes and conduits to the required lubrication points. These pumps are available in a variety of types and configurations, including gear pumps, piston pumps, vane pumps and centralized lubrication systems, each tailored to meet specific application needs.

Applications in Industry:

Lubrication pumps find application in a wide range of industries, from automotive to manufacturing and mining. Some of the common applications include:

- Industrial Machinery: In manufacturing and processing environments, lubrication pumps ensure proper lubrication of critical machinery components, reducing friction and wear.

- Automation: In automated systems, lubrication pumps provide continuous, automated lubrication, minimizing manual intervention and improving operational efficiency.

- Mining and Construction: On heavy equipment used in mining and construction, lubrication pumps ensure smooth and reliable operation, even in adverse conditions.

- Transportation: In commercial and transportation vehicles, lubrication pumps ensure proper lubrication of engines, transmissions and other moving components, extending service life and reducing maintenance costs.

Benefits of Lubrication Pumps:

The use of lubrication pumps in industry offers a number of significant benefits, including:

- Longer Equipment Life: By providing adequate and continuous lubrication, lubrication pumps help reduce component wear, resulting in longer equipment life.

- Reduced Maintenance Costs: By minimizing friction and wear, lubrication pumps help reduce costs associated with equipment maintenance and repair.

- Improved Operational Efficiency: By ensuring adequate lubrication at all times, lubrication pumps help keep industrial machinery running smoothly and efficiently, resulting in greater productivity and operational efficiency.

- Improved Safety: By reducing the risk of mechanical failure due to lack of lubrication, lubrication pumps help improve workplace safety by preventing accidents and injuries associated with defective equipment.

Considerations when Choosing a Lubrication Pump:

When selecting a lubrication pump for a specific application, it is important to consider a number of key factors, including:

- Lubricant Type: Consider the type of lubricant to be used and ensure that the pump selected is compatible with said lubricant.

- Flow and Pressure Requirements: Evaluate the lubricant flow and pressure requirements of the application to select a pump that can provide the necessary performance.

- Operating Environment: Consider the environmental and operational conditions in which the lubrication pump will operate, including temperature, humidity, and the presence of contaminants.

- Maintenance and Service: Evaluate the ease of maintenance and service of the pump, including access to spare parts and available technical support.

In conclusion, lubrication pumps play an indispensable role in optimizing industrial operation by ensuring adequate and continuous lubrication of equipment. By understanding the different types of pumps available, their industry applications, and associated benefits, companies can make informed decisions when selecting the right lubrication pump for their specific needs. With proper selection and regular maintenance, lubrication pumps can significantly contribute to improving operational efficiency, reducing maintenance costs and extending the life of industrial equipment.